Additionally, the operator must have an intensive idea of the processing application of your CNC machine Software, including the approach and Procedure, as well as the actions which the machine Software ought to perform.

In almost any situation, multi-axis vertical machine centers coordinated with CNC machine technology support to supply curved sections with accuracy and precision in an effective way as well as time utilized is minimum.

Any parts demanding high machining accuracy and great surface area roughness must be processed by machine tools, earning them a vital Consider The expansion of the manufacturing market and national overall economy.

The relative motion involving the tool along with the workpiece for cutting out these “no cost” styles is correspondingly sophisticated. In Procedure, it’s necessary to control the workpiece table as well as Instrument to maneuver in accordance with the intended place-time curve and reach the required situation with the specified Perspective at the desired time.

In the event the temperature is higher than this, it could show a challenge Using the lubrication and will be checked.

Indeed, you go through that suitable; another Tormach CNC Mill designed it on this listing. Some would call this the minimal brother of the more well-liked 1100M, but this tiny guy is trying to make some noise.

The various machine tools as well as parameters demanded for the pieces are transformed into facts codes that are by and huge satisfactory and readable with the numerical Regulate machine from the machine.

The vertical machining centers run on the look design of components. The various machine tools plus the parameters essential with the parts are transformed into details codes that are frequently appropriate and readable through the numerical control unit of your machine.

Down load CNC machines are contemporary subtractive manufacturing equipment, which instantly Handle the Software path and motion for content elimination.

The CNC vertical Explore machining centers are powerful for machining different industrial elements. These machines are adaptable and productive. They get rid of levels of fabric from a substrate to supply the specified element with numerous functions.

The CNC system’s capability to speedily course of action data enables multi-channel and fast signal acquisition and processing on the defective aspect. The diagnostic application then performs a logic analysis and judgment to ascertain when there is a fault during the system and quickly locate it.

In case you have an interest in almost any of All those fields or make smaller primary complex components, this machine is a good selection.

Parameter Check out the machine details from the NC machine Resource is a crucial parameter attained through a series of exams and adjustments, and that is the guarantee of the normal operation on the machine Resource.

Most CNC vertical milling centers use recalculating coolant systems to guarantee sections and cutter tools are very well lubricated. This coolant system typically utilizes water and soluble oil among many liquids.

Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now! Bill Cosby Then & Now!

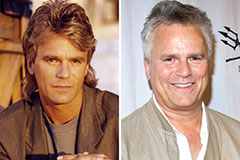

Bill Cosby Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!